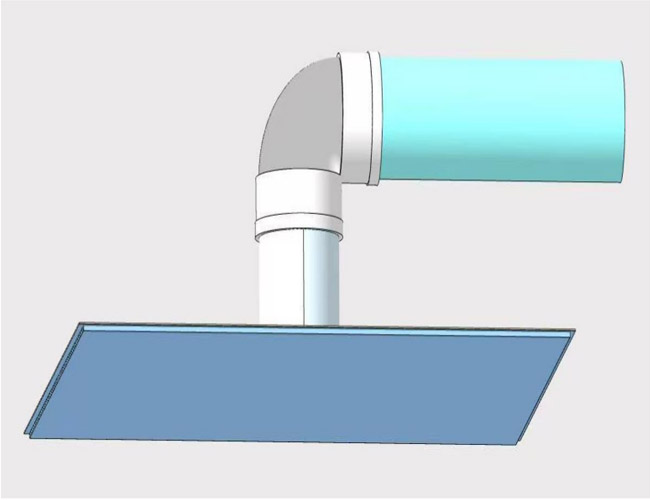

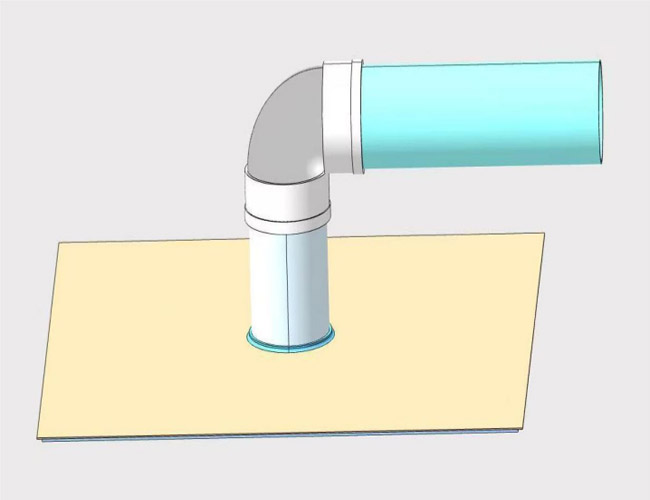

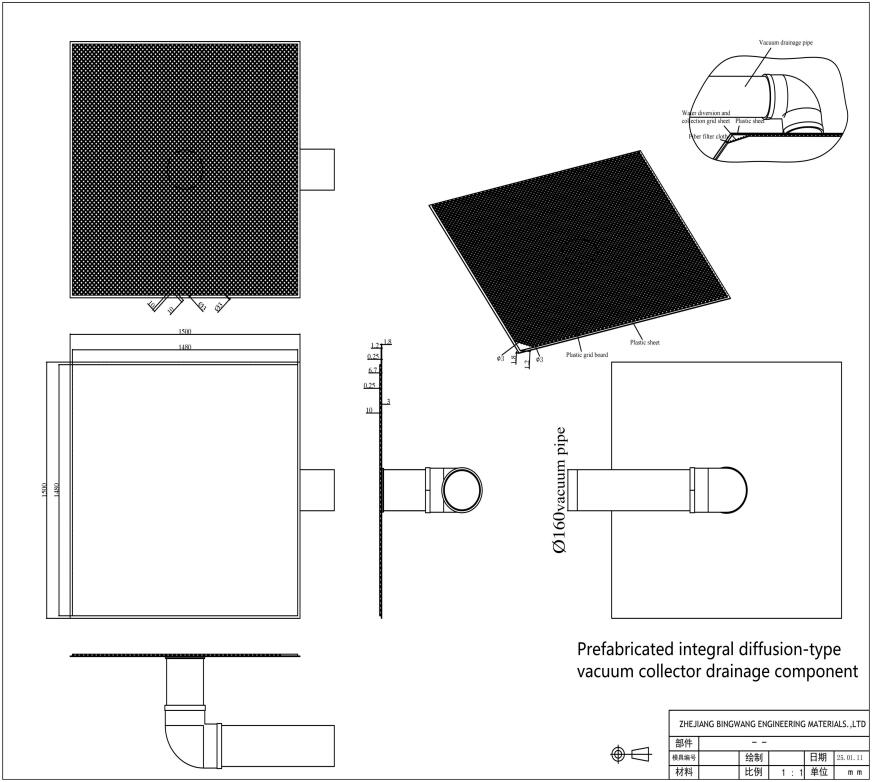

Prefabricated integral diffusion-type vacuum collector drainage component

The upper layer is made of 2mm-thick plastic sheets, the middle layer is made of plastic geogrids as a diversion drainage channel, and the lower layer is made of high-permeability fiber filter membranes, and these three kinds of materials are laminated, pressed, and fused to form an integral component; a hole is made in the center of the plastic sheet in the upper layer to be fused with the port of plastic vacuum tube. The component suction surface, with an area of 1~2.25m2, is stacked with a 1.5m-wide horizontal drainage board for suction and drainage; it replaces the application of sand layers and filter tubes. Its advantages are as follows:

(1) The hole in the plastic sheet is fused with the port of plastic tube to form a composite structure, and the area of the vacuum tube suction port is expanded to 1~2.25m2, improving the strength of negative pressure suction and the suction efficiency.

(2) The interface between the plane layer of the plastic sheet and the sealing membrane is fused and firmly and reliably sealed, with a large fusion area.

(3) The blockage of vacuum plastic pipe ports is avoided, the suction and

drainage flow rate is improved, the resistance is decreased, the drainage

flow rate is increased, the vacuum pumping time is reduced, and the

construction period is shortened.