Products

Drainage boards have been widely used in preloading drainage and consolidation treatment of soft soil foundations (such as mudflats, land reclamation by dredging, roads, airports, power plants, dams, bulk storage yards for minerals, container yards, waste landfill sites, workshop buildings, and warehouses) and solid-liquid separation treatment projects (such as environmentally friendly percolating fluid pools and ore washing pools).

Drainage boards are usually used in the treatment of soft soil foundations of engineering construction projects, which is a kind of the most eco-friendly, economical, effective, reliable, and mature water-air separation techniques through physical squeezing. After drainage boards are inserted into the soft soil layer, the drainage path can be shortened. With the action of heaped loads and vacuum loads, differential pressure is formed between soil body and drainage boards, water and air are discharged from the solid body to drainage boards through vertical drainage boards and horizontally longitudinal and transversal drainage boards, the soil body undergoes continuous consolidation, the settlement and uneven settlement of the soil body continues to occur/be eliminated, and the strength of foundation soil is constantly improving.

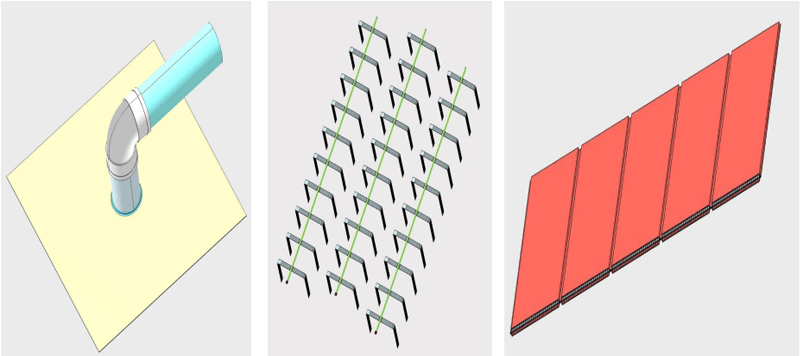

In the design, various technical factors, such as drainage board model (including structural characteristics, materials, performance indicators, etc.), drainage board layout (including

spacing and treatment depth), drainage board construction (including manual/mechanical construction, onshore/offshore construction, etc.), horizontal drainage form (including

horizontally longitudinal and transverse drainage boards, cushions with sand/stone, cushions without sand, etc.), preloading mode (including piling preloading/surcharge preloading, vacuum preloading, combined vacuum and piling preloading, etc.), loading time, and degree of consolidation, need to be comprehensively considered together with the actual

characteristics of projects, purpose of treatment, technical indicators after treatment for comparison of schemes to choose the best cost-effective

I. Bin Wang Integral Plastic Drainage Boards

Bin Wang integral plastic drainage board is made of high-quality plastic board core and high-performance filter membrane which are laminated, pressed, and fused.

1. High-quality plastic core boards

High-quality plastic core boards are made of 100% pure new polypropylene or polyethylene materials. The intelligent online monitoring technology is adopted to automatically control the amount of extrusion, ensure that the performance indicators of core boards, such as number of teeth, width, and thickness, can meet the requirements, and guarantee the stability of product quality. It is characterized by high strength, without breaking, bending, or inverted teeth, ensuring that there is no reduction in the water flow capacity capability (water flow capacity).

2. High-performance filter membrane

The high-performance filter membrane is made of high-strength fibers with uniform thickness and has a composite structure of lamination and fusion bonding. The intelligent online monitoring system is used to monitor temperature and pressure, and the quantity of fibers is automatically controlled to ensure the quality stability of filter membranes and ensure that various performance indicators, such as uniformity, porosity, high permeability, elongation, and high longitudinal and transversal strength, can meet the requirements. The resistance of high-performance filter membranes to chemical decomposition, damage, and clogging can ensure the durability and permeability of such membranes.

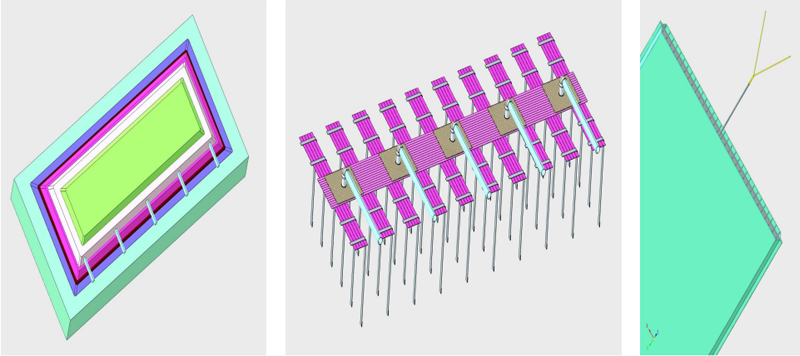

3. Integral high-performance drainage boards

Compared with traditional drainage boards, Bin Wang integral drainage boards have the following advantages:

(1) Filter membranes and board cores are laminated, pressed, and fused to form an integral structure. Filter membranes are not easy to crack, corners and edges are not easy to damage by friction, and board cores are not easy to break, ensuring the water flow performance of drainage boards.

(2) Integral drainage boards avoid the problem of inverted teeth generated by shrinkage of the core board edges during the production of traditional drainage boards, ensuring the water flow performance of drainage boards.

(3) The 500mm-1,500mm-wide horizontal drainage boards can replace the horizontal drainage application function of the sand cushion and also have the functions of geogrid reinforcement and geotextile anti-filtration.

(4) The adoption of electronic microwave depth sounding wires and the spray printing of digital scale marks can directly and repeatedly measure the construction depth of vertical drainage boards and be conducive to ensuring the authenticity of construction process data, improving and perfecting the supervision and management means of engineering quality.

(5) After samples are taken from drainage boards on site, a variety of performance indicators of filter membranes and drainage boards can be tested.

With these advantages, the permeability rate of drainage board filter membrane increases, the osmotic resistance decreases, the seepage flow rate increases, the water and gas in soft soil foundations are easy to discharge, the degree of consolidation is enhanced, the strength continuously increases, and settlement and uneven settlement are continuously eliminated to meet the requirements of use in the engineering projects, such as onshore projects, offshore projects, and projects in sewage environments.

Maintaining the vacuum degree and the capability of suction and drainage is determined by the permeability of fiber filter membranes, osmotic resistance, and attenuation rate of blockage; the use of high-strength and high-performance fiber filter membranes ensures the uniformity, porosity, high permeability, elongation, high longitudinal and transversal strength, and stability of other performance indicators of filter membranes. The resistance of high-performance filter membranes to chemical decomposition, damage, and clogging can ensure the durability and permeability of such membranes. Under the condition that filter membranes are not damaged and do not absorb mud, plastic core boards have sufficient rigidity and toughness, with unobstructed drainage channels

II. Supporting components of vacuum preloading integral drainage boards

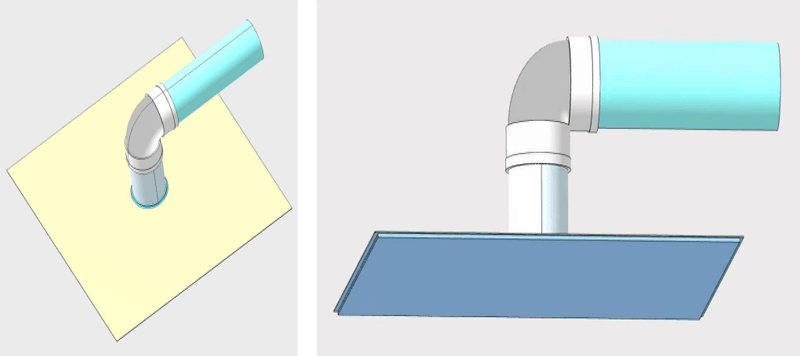

1. Prefabricated integral diffusion-type vacuum collector drainage component

The upper layer is made of 2mm-thick plastic sheets, the middle layer is made of plastic geogrids as a diversion drainage channel, and the lower layer is made of high- permeability fiber filter membranes, and these three kinds of materials are laminated, pressed, and fused to form an integral component; a hole is made in the center of the plastic sheet in the upper layer to be fused with the port of plastic vacuum tube. The component suction surface, with an area of 1~2.25m2 , is stacked with a 1.5m- wide horizontal drainage board for suction and drainage; it replaces the application of sand layers and filter tubes. Its advantages are as follows:

(1) The hole in the plastic sheet is fused with the port of plastic tube to form a composite structure, and the area of the vacuum tube suction port is expanded to 1~2.25m2 , improving the strength of negative pressure suction and the suction efficiency.

(2) The interface between the plane layer of the plastic sheet and the sealing membrane is fused and firmly and reliably sealed, with a large fusion area.

(3) The blockage of vacuum plastic pipe ports is avoided, the suction and drainage flow rate is improved, the resistance is decreased, the drainage flow rate is increased, the vacuum pumping time is reduced, and the construction period is shortened.

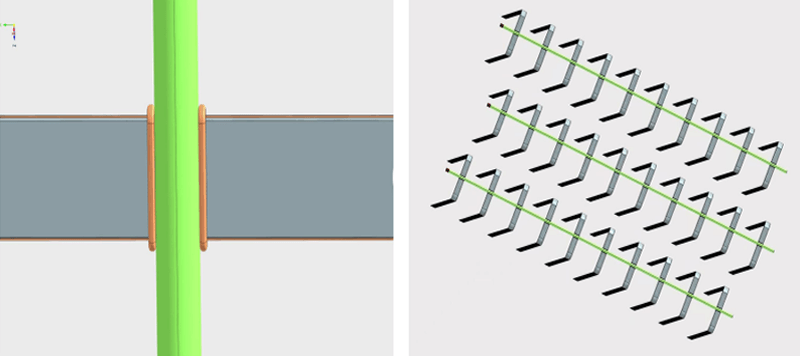

2. Vacuum-suction prefabricated integral drainage board fittings

The fittings are made of integral drainage boards with a prefabricated length and two ports through fusion and sealing and penetrate the perforated plastic pipe. The fittings are fixed to the holes at the connection with the hot-melt adhesive through fusion bonding, with the following characteristics:

(1) The connections are glued and sealed firmly to prevent the inhalation of silt.

(2) The fittings can be used for direct vacuum-suction water drainage and consolidation of the 5m ~ 7m shallow layer of supersoft silt, float sludge, and mud.

(3) The prefabricated integral drainage board fittings can replace the pipe connection process on the drainage board construction site, improving the efficiency of

construction.